In the context of globalization and the rapid development of the world economy, effective supply chain management is a “key” factor for the success of logistics units. RFID technology, with its ability to automatically identify and collect data remotely, has been and is the clearest evidence of the “revolution” in the way the supply chain operates. The following article will help you better understand RFID technology in logistics as well as the benefits that RFID brings to businesses, so stay tuned!

About RFID Technology

RFID stands for Radio Frequency Identification, which is a technology that uses radio waves to identify objects. RFID technology allows users to identify objects through a radio wave transmitting and receiving system, supporting fast, efficient, and accurate management.

Not only in Logistics, RFID technology is now widely applied in most fields, from library management, agriculture, and animal husbandry to healthcare, education, and more.

See details in “RFID Technology and Its Applications in Daily Life” to better understand modern RFID technology and its common applications.

How is RFID Used in Logistics and Supply Chain Management?

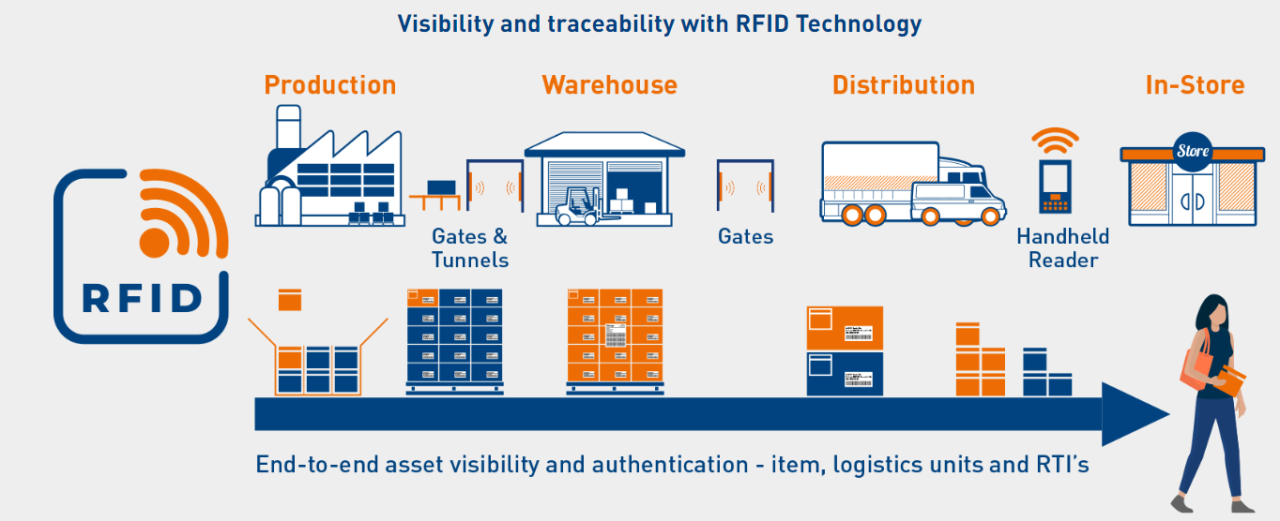

RFID has the ability to simplify and accelerate warehouse entry and exit processes, providing the exact location of each item in the warehouse, making it easier to find goods. RFID allows companies to track workflows in their supply chains. In addition, RFID tags also help units control and track assets, especially for high-value products and assets. Moreover, RFID can be applied to track inventory through warehouse management, transportation, and distribution centers.

Specific Applications of RFID in Logistics:

Warehouse Management

RFID enables the updating of detailed information about the quantity and location of goods in the warehouse. Moreover, RFID technology can read information from a distance of up to tens or hundreds of meters. This allows businesses to control inventory levels, thereby making timely decisions about importing and exporting goods, and allocating resources effectively.

RFID tags attached to individual products or pallets enable rapid and accurate location tracking within the warehouse, minimizing search time, improving efficiency, and optimizing costs. Furthermore, the RFID system allows for quick and precise recording of goods as they enter or leave the warehouse, thereby minimizing human error.

RFID tags enable efficient integration by quickly capturing crucial information about materials and products in transit. Subsequently, RFID readers facilitate seamless data transmission, ensuring that all parties involved in the supply chain receive prompt and accurate information.

Explore some of our best-selling RFID readers:

Utilizing RFID Technology in Transportation and Distribution

RFID tags attached to packages or transport vehicles enable the tracking of delivery routes, transportation time, and environmental conditions such as temperature and humidity, ensuring product safety and quality. Continuous updates on shipment information throughout the transportation process minimize the risk of incorrect deliveries and significantly reduce the likelihood of lost goods. Data on location and traffic conditions gathered from RFID-equipped vehicles allows businesses to make immediate and effective decisions, ensuring timely delivery and maintaining 100% quality of goods.

Utilizing RFID in Supply Chain Management

By implementing RFID technology, businesses can easily track the entire “lifecycle” of a product, from raw materials to finished goods. This enables them to control quality, trace origins, and determine shipment status more simply and conveniently.

Through the application of RFID technology in logistics, detailed and transparent information about goods is shared among manufacturers, suppliers, transportation units, and retailers, enhancing collaboration and streamlining warehouse management processes. Moreover, data collected through RFID technology ensures accurate recording and retrieval of all items, minimizing the possibility of lost goods. Additionally, real-time data provides greater accuracy in picking and inventory control.

Benefits of RFID Technology in Logistics

Beyond optimizing the receiving, storing, and distribution of products, implementing RFID technology in logistics offers numerous other significant advantages. Here are the key benefits of utilizing RFID solutions in logistics and supply chain management:

- Real-time Inventory Tracking: By applying RFID in logistics, businesses can accurately track the quantity of products they have, allowing them to assess overstocking situations and ensure that the amount of goods available on shelves meets market demand.

- Supply Chain Workflow Monitoring: RFID technology enables businesses to easily monitor workflows within the supply chain, collecting essential data related to equipment, inventory, and assets, facilitating automation and simplification throughout the entire process. This helps minimize errors in supply chain management and operations caused by human factors.

- Loss and Damage Prevention: RFID tags attached to goods help logistics units control inventory through a real-time product location system. This enables timely detection of lost, damaged, or even stolen goods, allowing for prompt and effective solutions.

- Counterfeit and Substandard Goods Detection: Each RFID tag is assigned a unique, non-replicable identification code. Each identifier can be linked to detailed product information such as production date, batch number, and manufacturer, creating an unforgeable record stored on a cloud platform. Therefore, applying RFID technology in logistics helps minimize the circulation of counterfeit, fake, and substandard goods.

- Automated Receiving, Storing, and Distribution: RFID solutions promote warehouse automation, from receiving and storing to distributing products. The RFID system optimizes product location and handling, reducing labor costs and overall company expenses.

- Faster Inventory Checks: RFID readers are strategically placed within the warehouse to scan and identify multiple items simultaneously, accelerating inventory checks and providing real-time inventory updates, reducing stockouts and overstocking situations.

- Enhanced Customer Experience: Today’s customers expect goods to be readily available at all times. Implementing RFID solutions in logistics and supply chain management allows suppliers to track products from entry to exit, ensuring product availability to meet customer demand. This not only reduces shortages but also effectively enhances the customer experience.

Challenges and Solutions in Implementing RFID Technology in Logistics

Despite its numerous benefits, RFID solutions also present significant challenges for businesses. The initial investment cost for an RFID system can be substantial, posing a barrier for small and medium-sized enterprises. Furthermore, in environments with a high presence of metals or liquids, radio waves from RFID can be disrupted, reducing the efficiency of the entire system. RFID can also encounter signal collision issues when multiple tags reflect the same signal, leading to difficulties in accurately reading data.

Proposed Solutions:

- Conduct a Thorough Cost-Benefit Analysis: Before investing in an RFID system, business owners should carefully analyze the investment costs, operating expenses, and potential benefits of RFID to ensure optimal economic efficiency.

- Seek a Reputable Vendor: Partner with a reliable and experienced RFID vendor to receive guidance on flexible solutions that can adapt to the future growth and evolving needs of the business.

- Choose the Right RFID Technology: Consider factors such as operating frequency, read range, interference resistance, and environmental conditions to select the most suitable RFID technology for the specific application.

Leading Provider of Reliable RFID Technology Solutions in Vietnam

IT Nam Viet is proud to be a pioneer in providing comprehensive and reputable RFID technology solutions in Vietnam. With over 10 years of experience and a team of seasoned experts, we are committed to delivering optimal, efficient, and cost-effective solutions that drive sustainable business growth.

IT Nam Viet specializes in providing: RFID tags and labels, RFID equipment, TSL RFID devices, barcode scanners, handheld printers, label printers, and more. Our team of specialists will understand your needs, advise, and implement RFID solutions tailored to the specific characteristics of each business. Moreover, we provide ongoing technical support, readily available to address your concerns 24/7, anytime, anywhere.

This article has provided detailed information about RFID technology in logistics and supply chain management. If you require consultation on RFID solutions or barcode technology, don’t hesitate to contact IT Nam Viet via our hotline (+84) 962.888.179 for prompt and effective assistance.

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt