In the context of automation and traceability becoming the standard in warehouse operations management, Cykeo’s CK-DP13C UHF RFID reader is considered a professional RFID reading and writing solution, designed to handle reading multiple tags at the same time, fast speed, outstanding performance, high stability.

Features of UHF RFID Reader CK-DP13C

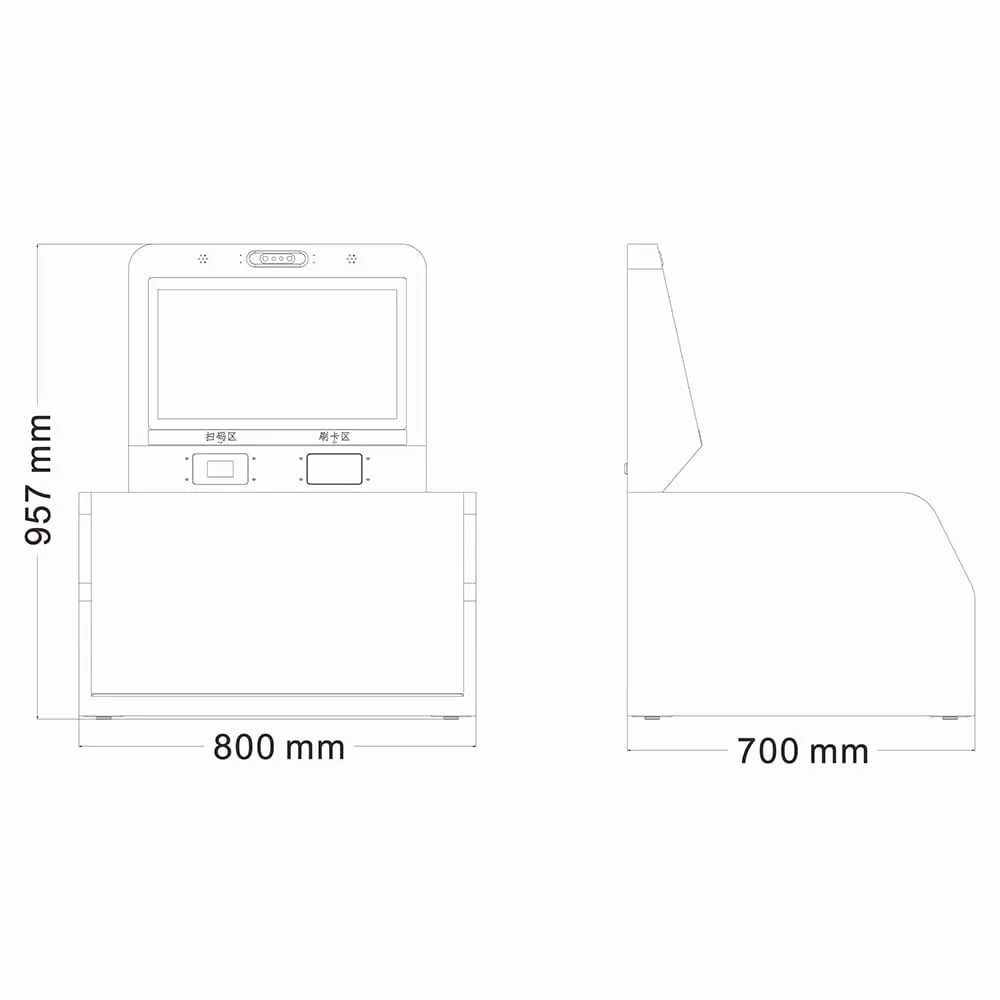

The CK-DP13C UHF Reader RFID Workstation delivers unmatched 40+ tags/sec reading performance with ISO 18000-6C compliance. Engineered with a 22″ multi-touch interface and carbon steel housing, this industrial RFID workstation excels in garment warehousing and medical linen tracking scenarios.

Optimal for bulk RFID operations: Apparel warehouse cycle counts, healthcare linen RFID tagging, retail stockroom verification, and industrial parts identification.

KEY BENEFITS OF CYKEO UHF READER RFID WORKSTATION

- 50+ Tags/Sec Batch Processing: Advanced anti-collision algorithm for simultaneous tag reading/writing.

21.5″ Capacitive Touch Interface: User-friendly read-write control with multi-touch gestures.

Signal Isolation Technology: Shielded antenna design prevents cross-read errors<0.1% interference rate

Dual OS Flexibility: Choose Windows 10i5-4th Genor Android 7.1RK3399configurations.

Industrial-Grade Durability: Carbon steel frame withstands 500kg vertical loads in harsh environments.

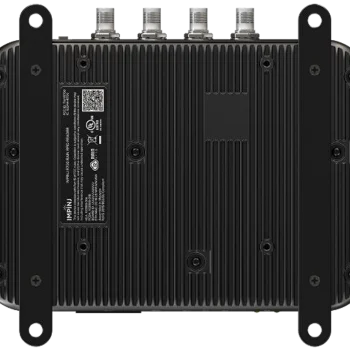

Multi-Protocol Support: Handles EPC C1G2, ISO 18000-6B, and optional HFmodules.

Expandable Connectivity: LAN port with optional WiFi/4G for ERP/WMS integration.

FAQs

How Does the UHF Reader RFID Workstation Optimize Apparel Inventory Management?

Industrial-Grade Solution: The CK-DP13C UHF RFID Workstation revolutionizes apparel logistics with:

- Batch Processing: Read 50+ garment tags per second (ISO 18000-6C compliant), ideal for high-volume warehouse audits.

- Signal Isolation: Shielded scanning chamber prevents misreads in dense clothing racks (tested with ≤5cm tag spacing).

- ERP Integration: Auto-export RFID data to SAP/Oracle via CSV/XML formats, reducing manual entry errors by 90%.

- Multi-Sensor Validation: Built-in weight detection verifies boxed inventory accuracy during RFID scans.

Typical Workflow: Workers place bulk garments on the workstation’s 22” touchscreen area → RFID antennas scan entire batches in 2-3 seconds → System syncs real-time counts with WMS dashboards.

Can This RFID Workstation Withstand Hospital Linen Sterilization Environments?

Healthcare-Ready Durability: Designed for medical textile tracking, the CK-DP13C delivers:

- Chemical Resistance: IP54-rated glass surface withstands daily disinfection with ethanol/bleach solutions.

- Thermal Tolerance: Operates at 60°C during autoclave-adjacent deployments, with condensation-proof antenna modules.

- Data Security: HIPAA-compliant audit trails record RFID tag scans with timestamps and operator biometric verification.

- Tag Survivability: Tested with 5,000+ wash cycles on RFID-embedded linens (UHF tags with 0.5mm encapsulation).

Use Case: Laundry staff process 200+ soiled bedsheets/hour → RFID tags survive high-pressure steam cleaning → Workstation updates linen lifecycle data in real-time.

What Makes This UHF Workstation Ideal for Multi-Protocol Logistics Operations?

Omni-Protocol Flexibility: As a central hub for mixed-technology environments:

- Hybrid Scanning: Concurrently processes UHF RFID (ISO 18000-6C), HF cards (ISO 15693), and QR codes in a single workflow.

- Frequency Agility: Auto-adjusts from 840MHz to 960MHz to bypass interference from forklift RFID systems.

- Edge Computing: RK3399 Android version pre-installed with middleware for parsing GS1/EPC tag data formats.

- Peripheral Expansion: Optional 4G/WiFi dongles enable cloud sync in warehouse dead zones.

Deployment Scenario: 3PL providers scan pallets with UHF tags → Verify parcel contents via QR codes → Authenticate drivers with HF ID cards → All data streams merge into a unified logistics dashboard.

Contact IT Nam Viet via Hotline (+84) 962 888 179 for consultation and quotation!

Tiếng Việt

Tiếng Việt