I. Why do we need to Apply RFID in warehouse management:

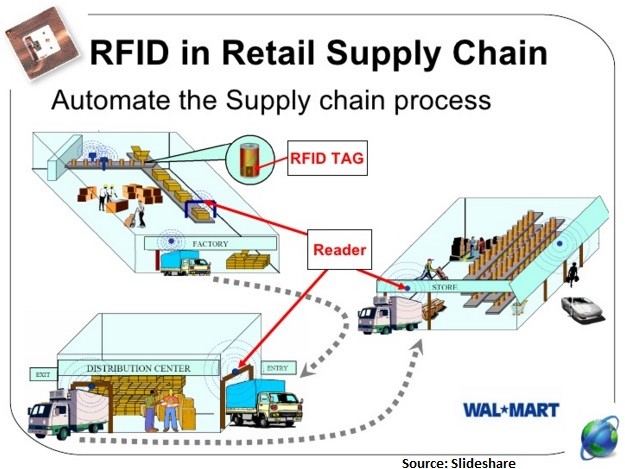

Surely everyone is familiar with the concept of barcode (barcode – containing basic information about the product). Barcode is widely used in warehouse management, supermarkets, hospitals… However, barcode has a disadvantage that only 1 label can be scanned at a time. RFID technology will help solve this problem by using a chip-based label that can read multiple labels at the same time. RFID (Radio Frequency IDentification – Radio frequency identification) is often used in large warehouses, RFID will help increase productivity, limit manual work in counting imported/exported goods & inventory, inventory management information will be updated accurately and quickly to the system.

RFID (Radio Frequency IDentification – Radio frequency identification) is often used in large warehouses, RFID will help increase productivity, limit manual work in counting imported/exported goods & inventory, inventory management information will be updated accurately and quickly to the system.

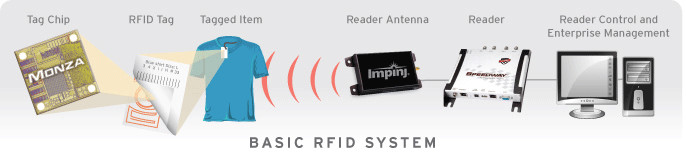

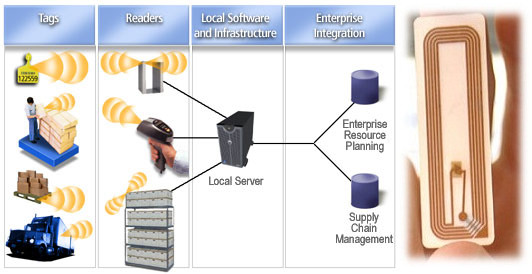

To apply RFID, you need:

2. RFID tag (Label): Used to stick on goods/boxes/packages/pallets….

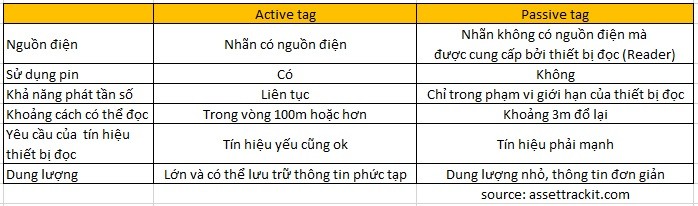

– Active tag: Tag can emit frequency and transmit to the reading device.

- The tag has a power source (usually a battery built into the tag) to maintain the chip’s circuit and emit a frequency.

- The price of this type of label is not cheap (about $25/piece or more), so it is only used for high-value items.

– Passive tag: Passive tag does not contain a battery, and the power is provided by the reader device. This type of label has more disadvantages than active tags, so the price is also cheaper, only about 10 cents/piece. Because of the low cost, it can be widely applied.

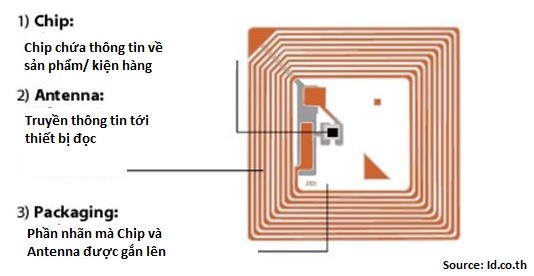

3. The structure of this passive tag includes:

Comparison between these two types of labels:

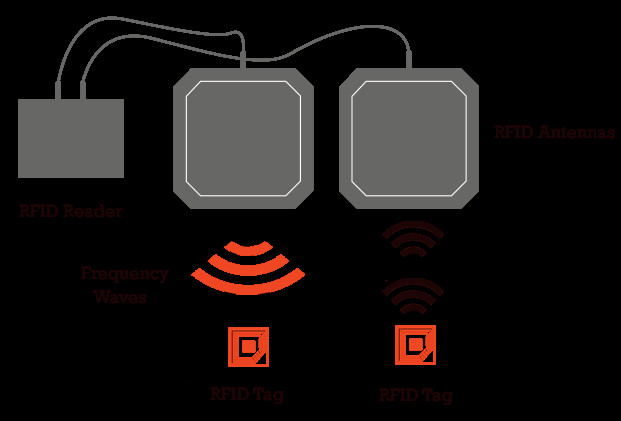

4. RFID Antenna (Receiver device that receives signals emitted from the tag)

The antenna in the tag will emit a signal. Antenna devices installed at many locations in the warehouse will receive the transmitted signal and transfer it to the RFID reader.

5. Reader: RFID reader

When receiving a signal from the Antenna (can use wireless technology to transfer the signal from the Antenna to the Reader), the reader will read the data and update it to the system.

II. What will the RFID application process be like?

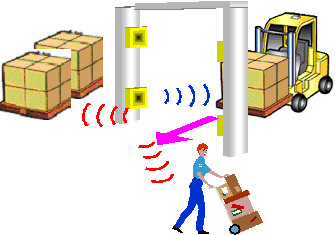

– Inbound: When importing goods into the warehouse, instead of warehouse staff having to spend time counting and updating the quantity to the system… Passive tags are attached to the package/product that already contains all information about the item, lot, date, origin,… When the entire package is brought through the reader installed at the import gate, this information will be updated to the system.

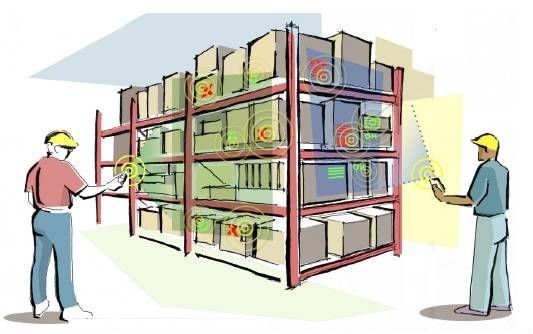

– Inventory: When goods are transferred to the rack position in the warehouse, the location will be automatically updated to the system thanks to the reader installed on the folklift. When counting inventory, you can use a handheld reader or a rack with a reader installed.

– Outbound/ Dispatch: At the exit gate, when the container is exported, the relevant information about the quantity of exported goods will be updated to the system immediately.

RFID application is being widely used, when applied to warehouse management, it will reduce headcount, minimize inventory errors, can trace back orders, …. and when having information quickly, it will help businesses plan more effectively.

III. Benefits of applying RFID in warehouse management:

- RFID application in warehouse management reduces business operating costs and increases profits.

- Proactively source capital thanks to low inventory and appropriate strategies.

- RFID system helps managers know when goods are out of date.

- Quickly and accurately determine the location of each product to reduce search time and pick up the wrong product.

- Manage product schedules during production or transportation.

- With tight integration and support in the business management system.

- RFID allows to reduce data entry operations, minimizing errors in business operations.

- https://chiprfid.vn/nhan-rfid-hieu-qua-trong-quan-ly-ton-kho-nhu-the-nao/

Vi. Choose the right RFID Chip:

- Locate the product to be RFID

- Operating environment of the RFID System

- Applicable product value.

- What is the monthly usage demand?

- Short RFID frequency (RF) or long distance (UHF).

- Density of goods in the warehouse.

- How to place the product to be tagged (high, low)

- Are there many metal objects on the shelves?

- Is the product reusable?

- How long does it need to be stored?

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt