The application of RFID in warehouse management brings many significant benefits to businesses, helping to automate processes, reduce errors, increase control capabilities and optimize operating costs. With the ability to identify objects by radio waves, RFID is gradually becoming an inevitable trend in modern warehouse management.

Understanding RFID Technology and Warehouse Management

In a “huge” warehouse, inventory management can be challenging for many, especially inexperienced staff. However, by implementing RFID in management, businesses can optimize time and save on personnel costs effectively.

What is RFID Technology?

RFID stands for Radio Frequency Identification, a technology that uses electromagnetic fields to automatically identify and track tags 1 enabled with this technology attached to objects.

An RFID system consists of 4 main components:

- RFID Tags: These are small devices that store data and transmit it wirelessly.

- RFID Reader: This device reads the data from the RFID tags.

- Antenna: This is the link between the tag and the reader, the RFID reader emits radio wave signals to activate and transmit and receive with the tag.

- Computer Software: This is the system that collects, processes data, and meets the requirements for monitoring, statistics, and control in the RFID system.

Let me know if you would like me to translate any other text!

Warehouse management is understood as what work?

Warehouse management is the process of controlling and tracking goods in the warehouse, from the stage of entering the warehouse to when they leave the warehouse. Specifically, warehouse management tasks include:

- Importing: Receiving goods into the warehouse.

- Exporting: Delivering goods out of the warehouse.

- Storage: Arranging and preserving goods in the best way possible.

- Inventory: Comparing the actual quantity of goods in stock with the data on the system.

Limitations of Manual Warehouse Management Methods

Manual warehouse management methods have several limitations, making it difficult for businesses to optimize their operating processes. Below are some of the limitations of the manual warehouse management method:

- Errors in manual data entry: Records of product information are not accurate.

- Time-consuming and labor-intensive inventory process: Requires many steps and the participation of many personnel, causing operating costs.

- Inefficient warehouse management: Frequent losses occur, delivery is delayed, thereby affecting the reputation of the business.

- Difficulties in transporting and storing goods: Lack of control over goods, leading to damage, loss, expiration, etc.

- Ineffective business operations: Inefficient warehouse management will make the business’s operations ineffective.

- Inability to adapt to market changes: With large operations, manual warehouse management methods can hardly adapt to changes in the market as well as customer needs, thereby limiting market expansion.

Therefore, the application of RFID in warehouse management is considered an inevitable trend for businesses to survive and develop sustainably.

What Benefits Does RFID Warehouse Management Bring to Businesses?

As mentioned, businesses that implement warehouse management with RFID technology will bring many practical benefits, specifically as follows:

RFID Warehouse Management Helps Optimize Process Efficiency

RFID tags help automate the warehouse management process, from receiving, issuing, storing, inventorying, tracking the location of goods in real-time, etc. This helps businesses and manufacturing facilities easily control goods and avoid unnecessary errors from humans. Moreover, automating the warehouse management process will help limit manual recording, improve accuracy, grasp accurate inventory information, thereby making better business strategies.

RFID Helps Increase Accuracy in Warehouse Management

By implementing RFID solutions in warehouse management, processes such as receiving, issuing, and storing will achieve higher accuracy, minimizing errors caused by manual data entry. Inventory data is updated continuously, giving businesses a more comprehensive view of goods in the warehouse.

Optimizing Costs and Improving Productivity Effectively

RFID helps automate many stages in warehouse management, reducing the number of necessary workers, helping businesses save budget effectively. Besides, RFID helps increase the speed of processing tasks in warehouse management, improve productivity, and significantly increase revenue.

Enhance Competitiveness Compared to Competitors

By applying RFID technology, businesses can quickly meet customer needs regarding delivery time and product quality. Therefore, businesses can provide services and products to customers in the best way, improve user experience, thereby contributing to increasing competitiveness compared to competitors in the same field.

In summary, warehouse management with RFID brings many benefits to businesses, helping businesses optimize operations, improve efficiency and competitiveness.

RFID Applications in Warehouse Management

Here are the applications of RFID in warehouse management:

Smart import and export management

The application of RFID technology supports the management of the import and export process accurately and quickly. When goods are imported into the warehouse, the RFID system automatically records information about the quantity of goods, date of import, storage location, etc. When there is a request for export, RFID helps to quickly locate the location of goods, minimizing search and order processing time.

With its non-contact reading capability (no line of sight required), RFID allows forklifts to automatically move through pallets of goods, record information, and update it into the system instantly. When goods are taken out, the application of RFID will help warehouse staff compare information with the order and confirm quickly, if there is a discrepancy, the system will immediately display a notification.

Flexible storage

The RFID system allows you to track the exact location of goods in the warehouse automatically, quickly, and almost absolutely accurately. The RFID tag is attached to the pallet of goods or products, the RFID system will automatically record their location in the warehouse, thereby helping to optimize the process of picking and processing orders. RFID has the ability to create a smart inventory management system, collect information about customer demand, based on which, businesses can come up with the most effective business strategies.

RFID application in warehouse inventory

RFID readers are capable of reading multiple RFID tags at the same time, thereby making inventory work in the warehouse many times faster than traditional methods. In large warehouses, robots automatically move through the aisles, scan RFID tags and collect data, saving time and inventory capacity.

RFID application in warehouse staff management

In addition to inventory control, RFID is also used to manage warehouse staff activities. By attaching RFID tags to employee cards or work equipment, the RFID system will record and track employee activities in the warehouse, thereby helping to increase transparency and security in personnel management.

RFID application in warehouse asset management

In addition, RFID also provides an optimal solution for managing assets in the enterprise’s warehouse. Assets such as machinery, equipment, pallets, vehicles, etc. will be attached with RFID tags containing detailed information about the assets. RFID then allows tracking of these assets through the entire supply chain loop and increases visibility on inventory locations. Thus, RFID helps prevent loss of warehouse assets by tracking the location and condition of assets.

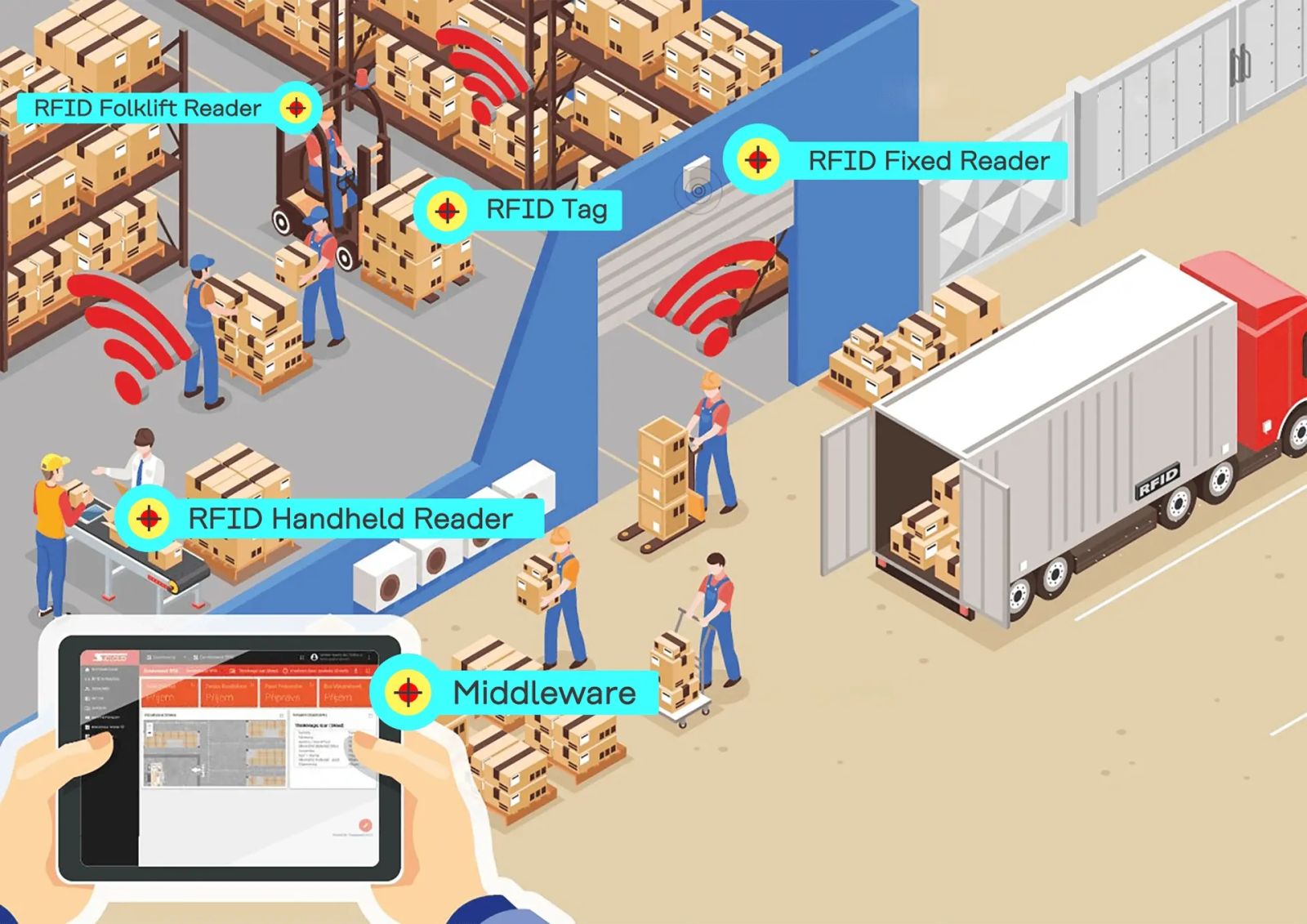

List of Required Equipment When Applying RFID Warehouse Management

Accordingly, the list of required equipment when applying RFID warehouse management includes:

- RFID Antenna: In the RFID system, the antenna plays an extremely important role, considered as the “right-hand man” of the reader, responsible for receiving and transmitting radio signals back and forth between the reader and the RFID card.

- Fixed RFID card reader.

- Remote handheld RFID reader.

- RFID data recording printer.

- RFID labels.

- RFID cables.

How Does RFID Work in Warehouse Management?

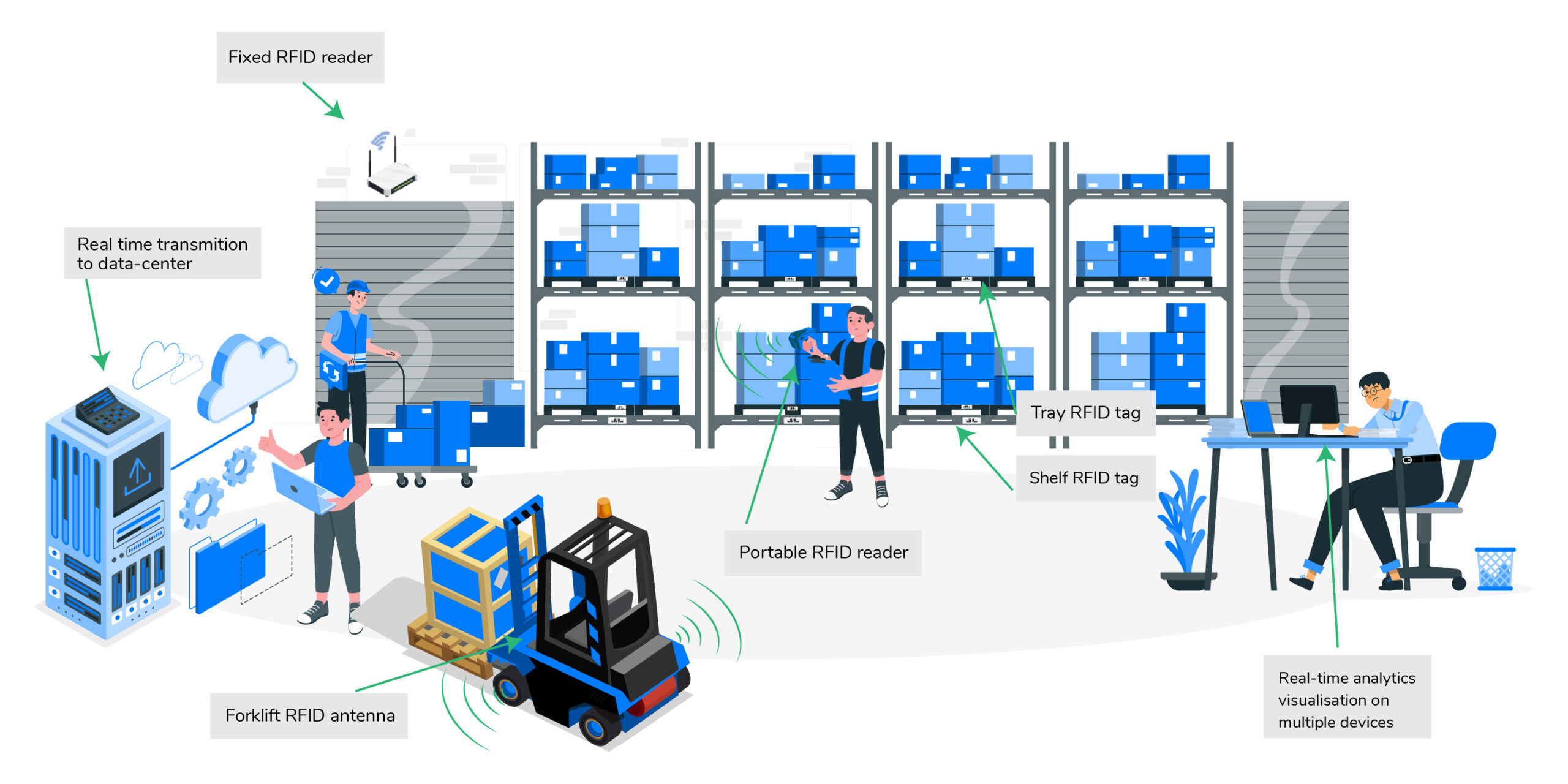

The RFID warehouse management system uses RFID tags attached to products and RFID readers to automatically track and locate goods in the warehouse. Here is how RFID works in warehouse management:

Register and attach RFID tags to products or pallets

First, businesses need to register the information of the goods in the warehouse management system and then attach RFID tags to the products, pallets or assets in the warehouse. Each RFID tag contains information about the goods such as product code, batch number, production date, expiry date, warehouse entry date, etc. Depending on the requirements, businesses can use passive RFID tags (RFID tags without internal power source), active RFID tags (use batteries) or semi-active RFID tags (use batteries but need signals from the reader to activate).

Transmit and receive signals, record the location of goods as soon as they are entered into the warehouse

The RFID card reader is placed in a suitable position to communicate with RFID tags. When the product or pallet is within the reader’s range, the reader will emit a radio signal to activate the tag. Once activated, the RFID tag will transmit data to the reader via radio waves.

When goods are entered into the warehouse, the RFID system automatically records their location in the warehouse. Therefore, every time goods are moved in the warehouse, the RFID system automatically updates the new location information, helping warehouse staff not to spend too much time searching.

Exporting goods from the warehouse

When there is a request to export goods, the warehouse staff will use the RFID card reader to confirm and retrieve the goods from the previously determined location. After exporting goods, the RFID system automatically updates the inventory information to reflect the remaining quantity.

Factors to Consider When Deploying RFID Systems in Warehouse Management

Deploying an RFID system is a strategic decision, requiring careful consideration of many related factors to ensure success and optimize benefits. Therefore, before deciding to invest in an RFID system, businesses need to consider the following points:

Cost of investing in an RFID system in warehouse management

The cost of deploying an RFID system depends on many factors: type of RFID card, type of RFID reader, RFID printer, software cost, installation cost, maintenance cost, related service fees, etc. At IT Nam Viet, we are committed to providing customers with quality, reputable RFID solutions in warehouse management at the best price on the market.

Contact Hotline (+84) 962.888.179 for advice on deploying an RFID system at a good price!

Training of RFID system operators

Accordingly, training of system operators is an important factor to ensure the success of RFID application deployment in warehouse management. Enterprises need to train warehouse staff on basic knowledge of RFID, RFID warehouse management process, how to handle incidents, etc. RFID technology and warehouse management process can change over time, so enterprises need to have a continuous training plan to update knowledge for employees.

Technology compatibility and integration issues

In fact, there are still many warehouses operating on old systems, which hinders the integration of RFID technology in warehouse management. Of course, to ensure compatibility, businesses need to upgrade or completely change the system, which is time-consuming and costly.

Reader conflict and card interference

Reader conflict occurs when signals from multiple RFID readers overlap, causing interference, leading to inaccurate data collection. In addition, card interference is also very common in warehouses because the environment contains metal materials, liquids, etc. Businesses need to have a clear assessment, plan, and test the system to identify and minimize potential interference problems.

Choosing a reliable RFID service provider in warehouse management

This is a “decisive” factor for the success of implementing an RFID warehouse management system. A reliable supplier will help businesses own quality, genuine equipment at prices commensurate with the value received. In addition, a reputable RFID technology supplier will accompany businesses throughout the system implementation process. IT Nam Viet is a reputable RFID technology supplier that businesses should prioritize.

Frequently Asked Questions When Deploying RFID Systems in Warehouse Management

For a deeper look at RFID technology in inventory management with RFID data centers, please refer to our answers below:

Does RFID increase inventory accuracy?

Using an RFID inventory management system has been shown to improve inventory accuracy by up to 13% compared to traditional inventory tracking methods and manual inventory checks in some situations. Especially in the retail industry, where maintaining inventory accuracy must be ensured continuously, RFID brings many significant benefits to businesses.

How to choose an RFID chip?

With our 10+ years of experience in the RFID field, we recommend that you consider the following factors before choosing an RFID chip:

- Accurately locate the products that need to be tagged with RFID for tracking: For example, metal products need anti-interference chips, small products need compact chips.

- The operating environment of the RFID system: Temperature, humidity, chemicals, etc. can affect the performance and lifespan of RFID chips, so businesses should prioritize choosing RFID chips that can withstand harsh environments.

- Applicable product value: The value of the RFID chip needs to match the value of the product, you should not use too expensive chips for low-value products.

- What is the monthly usage demand, from there consider choosing the appropriate type of label, optimizing the budget.

- RFID operating frequency is LF, HF or UHF, depending on the specific application to choose the appropriate RFID frequency.

- Warehouse density: Warehouse density affects the reading ability of the RFID reader, for warehouses with high density of goods, you need to choose a chip with good reading ability.

- If the product needs to be reused, you need to choose a durable RFID chip.

- How to arrange and lay out the products that need to be tagged.

- How long should the product be stored?

- …

If you do not have experience, it is best for businesses to seek advice from experts, they will help you make the optimal decision, ensure the system operates effectively and meets the needs of the business.

Is warehouse management using RFID technology difficult?

Operating the RFID system may cause little hindrance to warehouse staff, especially those who are new to this advanced technology. However, if properly trained and practiced regularly, this technology is not too difficult for company staff.

Does RFID price increase regularly?

As mentioned, RFID chip prices or RFID system deployment costs are likely to change depending on the time. However, in recent years, RFID prices have decreased significantly, helping to optimize the budget for businesses effectively.

What should be noted when using RFID in warehouse management?

To bring high efficiency in warehouse management using RFID, businesses need to note: ensure the system is operated according to the correct process; arrange goods in the warehouse neatly; the network system needs to be stable; train staff to understand RFID; need to back up the plan when operating; periodically check the system; …

The above is information about RFID applications in warehouse management that businesses need to refer to. IT Nam Viet is proud to be the leading prestigious RFID supplier in Vietnam, committed to bringing businesses the best quality RFID solutions at reasonable prices. If you need advice on RFID, please contact us via Hotline (+84) 962.888.179 for detailed advice!

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt