In the era of automation and digital transformation, the industrial laundry industry has been facing a big problem, which is how to control thousands of items every day with absolute precision, without causing loss? The comprehensive solution now is to apply RFID tags in industrial laundry, helping to automate the washing, drying, and quick delivery process. IT Nam Viet is proud to be a professional RFID service provider in Vietnam, with quality, good price and lifelong companionship with the project.

Challenges in Industrial Laundry Management

The industrial laundry industry plays an extremely important role in the operation of hotels, resorts, hospitals, factories, etc. However, the increasingly large scale will bring about significant challenges in the control, classification and traceability of fabrics. Counting, classifying as well as performing manual delivery will more or less lead to errors, causing product loss, significantly damaging the reputation of the business.

In addition, traditional industrial laundry management will make it difficult to evaluate fabric quality, plan replacements, trace the origin, and life cycle of fabric products. In addition, managing industrial laundry products will cost businesses a lot of operating costs, including labor, books, etc.

On the other hand, currently, the industrial laundry industry lacks tools to measure and optimize performance, making it difficult for managers to grasp actual output and cannot report in real time to make necessary improvements.

In particular, in the context of digital transformation of the service industry, corporate customers such as hotel chains, hospitals, industrial parks, etc. are requiring service providers to report online and transparently. Therefore, if advanced technology is not applied, laundry units will gradually lose their competitive advantage, thereby affecting the issue of promoting future development.

RFID in industrial laundry is becoming an inevitable solution to help businesses automate the entire process, improve productivity and increase transparency in management.

Benefits of Applying RFID Tags in Industrial Laundry

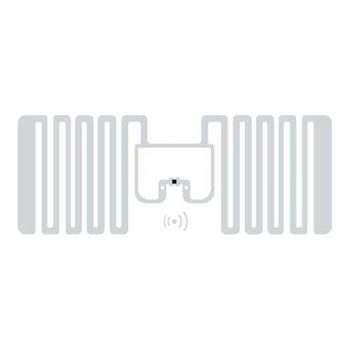

RFID is an identification technology that uses radio waves to transmit and record data between RFID tags and RFID Readers to create control points. Unlike barcode technology, RFID allows hundreds of tags to be read at the same time, reducing processing time in the laundry process by 80 – 90%.

Below are the benefits of using RFID in industrial laundry management:

RFID helps save costs effectively

Instead of having to manually count and record, RFID technology allows the reader to automatically identify hundreds of fabric items in just a few seconds. From receiving, sorting to drying, washing, packing, handing over,… all are automatically recorded by the system in real time, quickly, effectively, limiting errors caused by humans. RFID helps businesses save up to 80 – 90% of processing time, increase production line productivity by 30 – 50%, then businesses will save significantly on labor costs.

RFID application in industrial laundry helps smart management

With RFID solutions, laundry units will easily track order processing progress, inventory, search, and quickly ship goods, support management reporting, and allow for accurate and fast data extraction. Each RFID tag is only attached to one product with a unique ID code, allowing businesses to track detailed usage history, including number of washes, usage time, status, customer history, etc.

Thanks to transparent data, managers can easily control fabric quality and plan timely replacement. Obviously, this is extremely important for hospitals and hotels – where the management of thousands of highly hygienic products is required.

Effective risk management

The RFID system helps to automatically compare the quantity and type of fabric when importing and exporting goods, ensuring 100% accuracy. RFID helps inventory and management work to be performed accurately, without loss, data is recorded immediately, helping reporting and handover clearly and transparently.

Improve service quality

Thanks to the ability to manage transparently and with absolute accuracy, laundry units can provide detailed reports and proof of traceability to partners and customers. This helps increase professionalism and brand reputation, thereby building trust with business customers, especially in long-term cooperation models. With RFID solutions, customers can look up the status of laundry – return in real time, making the service more reliable than ever.

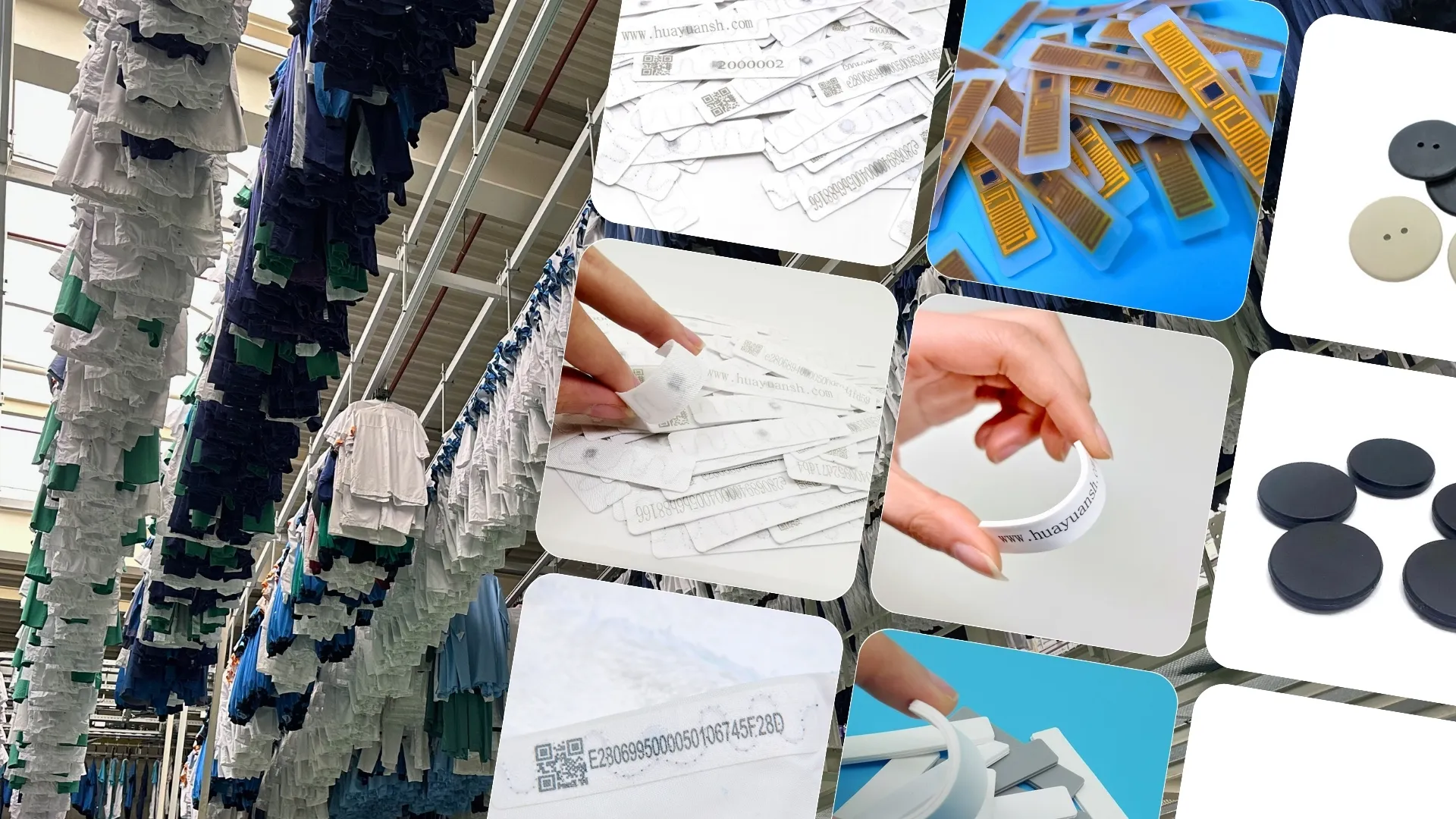

Types of RFID Tags in Industrial Laundry

In industrial laundry, choosing the right type of RFID tag plays a key role in ensuring accuracy, longevity and recognition performance. Depending on the fabric material and working environment, you need to choose a specialized RFID tag with heat resistance, water resistance and durability through many washing and drying cycles.

Below are the top 5 types of RFID tags in industrial laundry, readers can refer to:

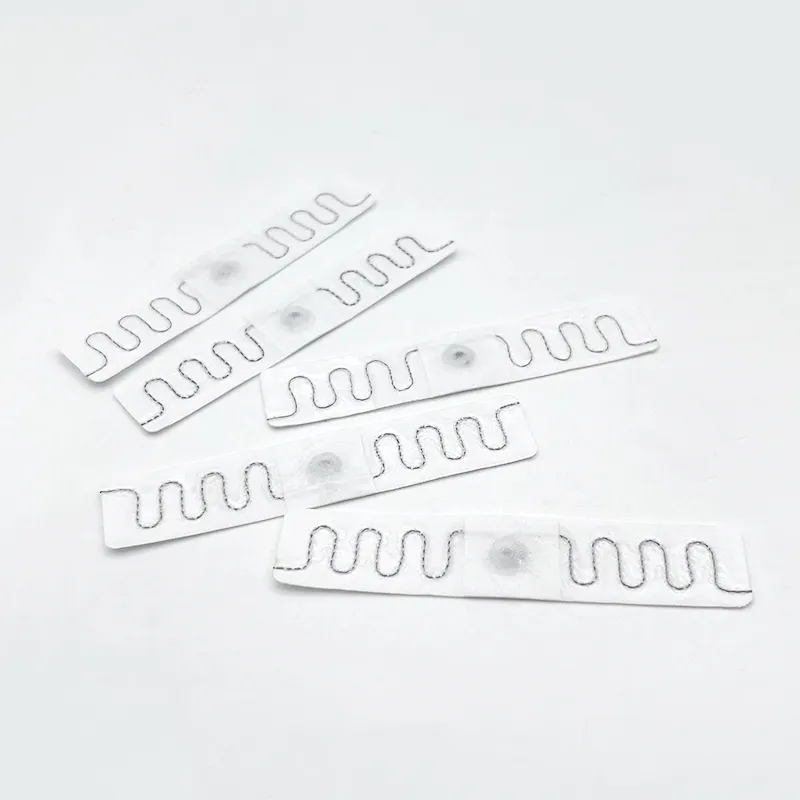

Hanging RFID tag

Hanging RFID tags are flexible tags that are attached directly to clothing, uniforms, towels, or other products. This type of tag is durable and can withstand high temperatures and pressures. This RFID tag is often used in the management of employee uniforms, protective clothing, etc. The advantage of this RFID tag is that it is easy to attach, easy to remove, and compatible with most types of RFID readers.

Heat-laminated RFID tags

Heat-pressed RFID tags are fixed on clothes by high-temperature hot pressing method, stable for a long time. This is one of the types of anti-counterfeit RFID tags that are quite popularly used today. The advantage of this type of RFID label is that it is difficult to peel off, can withstand high temperatures, and is flexibly applied in high-end products, corporate uniforms, etc.

Woven RFID tags

Woven RFID tags are fabric labels that have RFID chips integrated into the textile fibers, with electronic identification functions and brand information, sizes, etc. This is a compact, highly aesthetic solution with outstanding durability. These RFID tags are often used in the garment, fashion, and export clothing industries, etc.

PPS RFID Tags

This is a round candy-shaped RFID tag, made from heat-resistant PPS material, resistant to impact. This RFID tag is often attached directly to bed sheets, towels, medical uniforms, etc. The outstanding advantage of this type of tag is its ability to withstand high temperatures up to 200 degrees Celsius, and works well and stably through hundreds of washing and drying cycles.

Silicone RFID Tag

Silicone RFID tags are flexible and chemical resistant, and can be attached to towels, curtains, uniforms, etc. Silicone RFID tags are waterproof, heat resistant, durable, suitable for many different types of fabrics, supporting effective product counting and management.

Factors to Consider When Choosing RFID Tags in Industrial Laundry

Accordingly, when choosing RFID cards in industrial laundry, you need to note the following points:

Durability of RFID laundry tags

This is the most important factor that you need to consider when choosing RFID tags in industrial laundry. You need to prioritize choosing RFID textile tags that can withstand high temperatures and are resistant to chemicals, usually made from PPS or silicone. Besides, you need to pay attention to the quality of processing, including the method of sewing or attaching RFID tags because this will more or less determine the lifespan of the RFID tag.

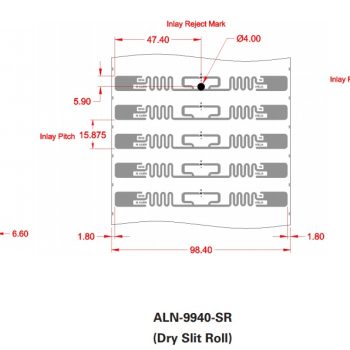

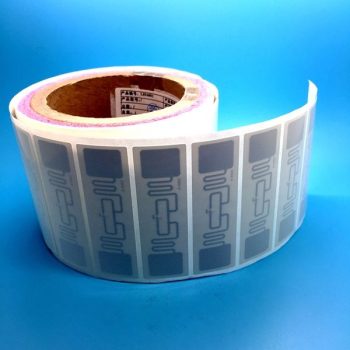

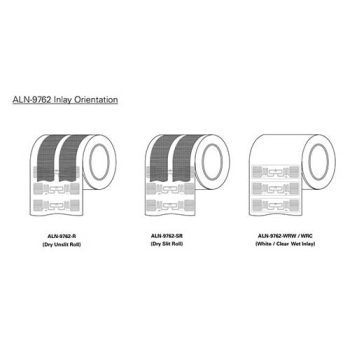

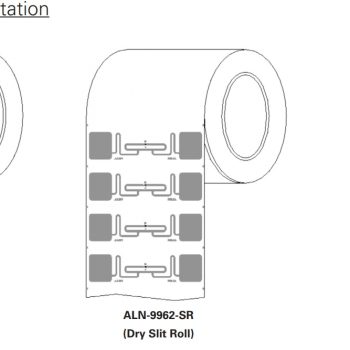

Collection of RFID tags in industrial laundry trusted and chosen by customers at IT Nam Viet:

RFID tagging method

Accordingly, the two preferred methods of RFID tagging in the laundry industry are direct sewing and heat pressing. Choosing which method will be suitable for each type of laundry, equipment as well as laundry service requirements.

Reading distance and performance

The reading distance of RFID tags will determine the effectiveness in the tracking process. Accordingly, factors affecting the reading distance and performance include: antenna design, transmission power, environmental factors, etc. RFID tags have many different frequencies, including low frequency RFID tags, high frequency RFID tags and ultra-high frequency RFID tags. However, in the industrial laundry industry, UHF RFID tags are preferred because of their long reading distance, ability to read hundreds of tags at the same time, and compatibility with RFID readers.

RFID Tag Application Process In Industrial Laundry

The process of using RFID cards in the industrial laundry industry is carried out in the following steps:

- Register clothing information including code, name, material type, style, unit or individual using.

- Attach RFID tags to clothes, each tag contains a unique ID code.

- When customers send clothes to the industrial laundry, the RFID reader at the reception area will automatically scan all tags in seconds, no need to manually count, which is time-consuming.

- When the product goes through each washing and drying stage, the reader system at each station will automatically update the product status, including being washed, being dried or waiting for inspection, handover, etc.

- After washing and drying, the products are put on the conveyor belt, the system automatically reads all RFID tags, classifies by customer, area or by product, etc.

- In the packaging area, the manager can use a handheld RFID scanner to re-check the products in the shipment, ensuring the correct quantity and fabric type before leaving the warehouse. The software will automatically compare with the original list, issue warnings if there are missing, extra or wrong codes, etc.

- When the goods are returned to the customer, the RFID reader system at the delivery area will automatically confirm. All data is synchronized in the RFID management software, creating a summary report by customer, date, area, product type, statistics on the number of washes, etc.

FAQs – Frequently Asked Questions About RFID Tags in Industrial Laundry

RFID technology is becoming a core solution to help the industrial laundry industry automate, optimize costs and improve accuracy. Below are answers to some of customers’ questions about RFID tags in the laundry industry:

Is the cost of implementing RFID for industrial laundry high?

YES. RFID costs depend on many factors: scale, number of readers, RFID tags, management software, etc. Compared to traditional technologies, investing in RFID deployment in the management and operation of industrial laundry systems will cost the unit more. However, in the long run, the benefits that RFID brings will be many times higher than other solutions, helping to reduce 80 – 90% of counting and data entry time, reduce labor costs, significantly limit losses, etc.

Can RFID tags withstand high temperatures?

YES. RFID tags can withstand high temperatures up to 200 degrees Celsius, are waterproof, and operate stably in industrial laundry environments. In addition to available RFID labels, IT Nam Viet also designs and manufactures RFID tags with chip types, sizes, and materials according to customer requirements.

How many RFID tags can an RFID reader read at once?

Depending on the type of RFID card reader as well as the installation environment, a reader is capable of reading up to thousands of RFID cards in a very short time, operating stably even when the cards are in a laundry bag.

Can RFID tags be attached to all fabrics?

YES. However, you need to choose the right tag location, avoiding high friction areas or fabric edges, this will help prevent the tag from peeling off, ensuring durability through many industrial washing and drying cycles.

IT Nam Viet – Professional Industrial Laundry RFID Solution Provider in Vietnam

IT Nam Viet is proud to be one of the pioneers in the field of providing RFID in Vietnam, with more than 10 years of experience, a trusted partner of hundreds of large and small businesses nationwide.

Nam Viet IT provides complete RFID solutions including:

- Processing RFID cards, heat-resistant and chemical-resistant RFID labels.

- Distributing a variety of genuine RFID card readers and RFID accessories.

- Consulting, installing and maintaining RFID systems nationwide.

At IT Nam Viet, we always conduct on-site surveys before offering suitable solutions to customers. This helps ensure the system operates smoothly, stably, and meets the requirements of each business. In addition, we are committed to providing competitive, reasonable quotes, commensurate with the value that customers receive.

Above is information about RFID card applications in the industrial laundry industry that readers should refer to. If you need advice on RFID technology as well as genuine RFID equipment and accessories, please contact IT Nam Viet via Hotline (+84) 962 888 179. We are ready to serve customers 24/7, dedicated, thoughtful, and with the highest sense of responsibility.

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt