RFID cards have been widely used in many different fields, typically transportation, healthcare, warehouse management, etc. However, the RFID card production process includes many complex stages, from design to output quality testing, etc. The following article by IT Nam Viet will help you explore the steps of producing RFID cards, labels, tracking and don’t miss it!

RFID Tag Overview

RFID tags are designed to store and transmit information via radio waves and identify objects. Based on various criteria, RFID tags are classified into: low-frequency RFID tags, high-frequency RFID tags, and ultra-high-frequency RFID tags. In addition, based on the power source, RFID tags are divided into active RFID tags, passive RFID tags, and semi-active RFID tags.

Accordingly, the structure of an RFID card includes the following basic components:

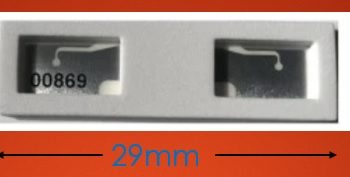

- RFID Chip: RFID ICs are integrated circuits that contain all the components of the controller, memory, and microprocessor. RFID ICs work by receiving energy through the waves emitted by the antenna from the RFID card reader, using that energy to transmit signals back to the reader.

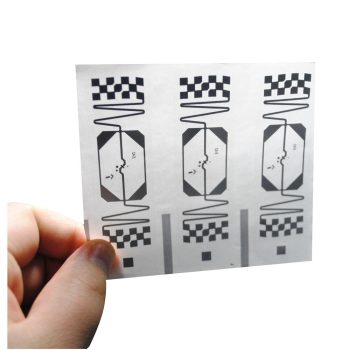

- Antenna: This is the part that connects to the chip and is responsible for receiving radio waves and transmitting information signals between the RFID card and the RFID reader. The antenna material is usually made of conductive material, typically metal.

- Substrate: This is the protective shell of the RFID card and is responsible for fixing the parts of the card. The substrate is usually a durable, impact-resistant polymer or plastic sheet that supports the attachment of RFID tags to various surfaces.

As mentioned, RFID technology or RFID cards have been widely applied in many areas of life, typically: RFID in healthcare management, RFID in access control to enhance security, RFID in warehouse management,…

Top 6 Steps in RFID Tag Manufacturing Process

Below are 6 steps to produce RFID cards that readers can refer to:

RFID label design and programming

The RFID tag manufacturing process begins in the design phase. At this point, RFID label manufacturing facilities and units will determine the size, shape, RFID frequency, etc. based on actual application requirements. Of course, to design and program RFID tags, we need to conduct a survey and understand factors related to the operating environment, industry, etc. After that, Nam Viet IT will manufacture antennas and microchips according to design specifications.

Consider choosing the right materials and technology

Choosing the right materials and technology is an important step that greatly determines the performance, durability and cost of deploying an RFID system. Accordingly, the materials used to make RFID cards are paper, PVC, PET, fabric (used in fashion), composite, etc. Depending on the operating environment, the RFID tag surface, investment costs, etc., you should consider and choose the appropriate material.

In addition, based on the card’s power source, you have the choice of passive or active RFID cards, etc. Passive RFID cards no longer have an integrated power source, they receive energy from radio waves emitted by RFID readers, use this energy to power the chip and respond to signals containing information. Passive RFID cards are cheaper, helping to optimize the budget for businesses.

Meanwhile, active RFID tags are equipped with batteries, allowing them to automatically emit signals without waiting for energy from the RFID reader. Active RFID tags have a long reading range, large storage capacity, and a somewhat higher price. Active RFID tags are often used in the field of access control to enhance security,…

Printing and coding stage

Accordingly, RFID label manufacturing and processing units will use specialized RFID printers to print and encode information onto RFID chips. This process includes printing text and image information on RFID labels and recording information onto RFID chips.

RFID chip

After printing and encoding, the RFID chip is attached to the RFID tag. This can be done by encapsulating the chip in a protective plastic layer or by attaching it directly to the label surface.

Cutting and packaging

Thẻ RFID sau khi được gắn chip RFID sẽ được cắt thành các hình dạng và kích thước theo yêu cầu trước đó của khách hàng. Sau đó, thẻ RFID được đóng gói để đảm bảo cho quá trình vận chuyển và ứng dụng trong các lĩnh vực khác nhau.

Cutting and packaging

Before the RFID card is shipped and delivered to customers, we perform card quality testing to ensure that the RFID chip is stable and the information is encoded correctly. After completing the production and quality testing process, the RFID card will be shipped and distributed to partners and customers.

Notes When Producing RFID Labels

Producing RFID labels is not simply printing a label, it is a technical process that requires precision from the selection, encoding to card quality testing.

Below are important notes that you need to know when processing RFID labels:

- Clearly define the need for use, whether it is for asset management tracking, warehouse management, anti-counterfeit RFID, or RFID access control to enhance security, etc. This will help you decide on the appropriate type of card that meets the function effectively.

- Determine the operating environment, cold storage environment, humid environment or chemical environment containing many solvents, etc. Based on this, you will determine whether the RFID tag surface is metal, plastic, wood, or liquid, etc. Note that RFID tags can be interfered with when they operate in liquid or metal environments.

- Consider and choose the right type of card, technology, RFID frequency, etc. You can access the article: “Criteria for Choosing RFID Tags Suitable for Each Business” to learn more about this issue.

- After labeling, take the product through the RFID test reading ports in the actual operating environment, helping to detect reading performance problems early before deploying synchronously on a large scale.

Nam Viet IT – RFID Label Processing According to Customer Requirements

Nam Viet IT is proud to be known as one of the prestigious units in the field of providing RFID technology as well as RFID devices, typically including: RFID cards, RFID readers, RFID printers,… Besides available RFID cards, Nam Viet IT also provides “tailor-made” solutions according to customers’ requirements, meeting the right usage needs and investment financial capacity.

Before processing RFID labels according to requirements, IT Nam Viet conducts a field survey, consults on choosing RFID frequency, ensures reading range, speed as well as security suitable for the enterprise system. IT Nam Viet accepts processing RFID plastic cards, RFID labels, anti-interference RFID cards, RFID bracelets,… We support the design of models, sizes and shapes of RFID labels according to the customer’s brand identity. We ensure that RFID card information is accurately encoded, secure, of superior quality and high durability.

Reasons to choose RFID card processing at IT Nam Viet:

- The staff are experts, experienced technicians, well-trained, dedicated, responsible.

- Committed to using chips and materials from reputable brands, ensuring outstanding performance and durability.

- Provide a complete solution from consulting, design, production to support, accompanying customers.

- Competitive, reasonable quotes, commensurate with the value customers receive.

If you need advice on RFID cards or RFID technology for your business, please contact us via Hotline (+84) 962 888 179!

Frequently Asked Questions About RFID Tag Manufacturing

Below are some answers to customer questions about the RFID card production process, readers can refer to more:

What materials are used to make RFID tags?

Materials used to make RFID tags include: paper, plastic, synthetic materials, hard cards, fabrics, etc. Paper is low cost and is used in making one-time RFID labels. Antenna materials are usually copper, aluminum or silver.

Are RFID tags customizable?

YES. You can change RFID tag parameters such as shape, size, surface printing, material,…

How long does it take to produce RFID tags?

Accordingly, the production time of RFID cards depends on the number of cards, the level of customization, the type of card, etc. Normally, this process can take from a few days to a few weeks. Please contact IT Nam Viet directly via Hotline 0962 888 179 for advice!

Above is detailed information about the RFID card production process that customers can refer to. If you need professional RFID solution advice, do not hesitate to connect with us via the platforms below.

- Company address: Company address: 177/22 National Highway 1K, Linh Xuan Ward, Thu Duc City, Ho Chi Minh City

- Showroom and office address: Showroom and working address: Office 27/13/9C, Street 27, Hiep Binh Chanh Ward, City. Thu Duc, Ho Chi Minh City

- Branch in Cambodia: No. 6 Street 24BT, Thnaot Chrum, Boeung Tumpun 2, Khan Mean Chey, Phnom Penh

- Hotline: (+84) 962.888.179

- Email: info@chiprfid.vn

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt