RFID textile has become a trend chosen and applied by large enterprises and corporations. RFID brings many practical benefits, automates operating processes, optimizes costs, and minimizes unnecessary errors caused by humans. Our article below will help readers better understand the application of RFID in garments, don’t miss it!

Overview of RFID Textile Solutions

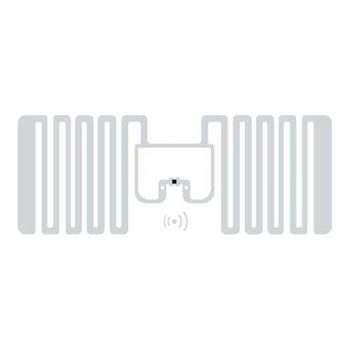

RFID is a radio wave object identification technology that allows reading and writing data from RFID tags attached to products without direct contact. In the textile industry, RFID is used to manage production, warehousing, warehousing, retail, etc.

Previously, barcode technology was considered a “revolution in goods management”, RFID is its 4.0 version. RFID has the ability to read hundreds of RFID tags at the same time, allowing real-time tracking and management of goods. An RFID system needs to ensure the following basic components: RFID labels, RFID card readers, antennas and management software.

Benefits of Applying RFID Technology in the Textile Industry

Nowadays, applying RFID solutions in the textile industry is no longer an “experimental” choice, it is an inevitable trend when global retail corporations such as Walmart, Zara, H&M,… all set RFID as a mandatory standard in the supply chain. Regarding this issue, readers can refer to the article: “Walmart Uses RFID Technology Effectively in Retail and Supply Chain“.

For garment corporations and businesses in Vietnam, the use of RFID will help bring a series of outstanding benefits, from operational management to meeting international compliance requirements.

Specifically as follows:

Fast warehouse management

RFID makes warehouse management more accurate and faster. Instead of spending hours and days manually counting, RFID allows users to simultaneously scan hundreds or even thousands of RFID tags at the same time.

The most obvious proof is that in the past, a fashion store had about 20,000 SKUs (product codes), manual inventory time could take about 2-3 days. Meanwhile, by applying RFID technology, that number is only about 2-3 hours, helping businesses save time and optimize human resources and operating costs,…

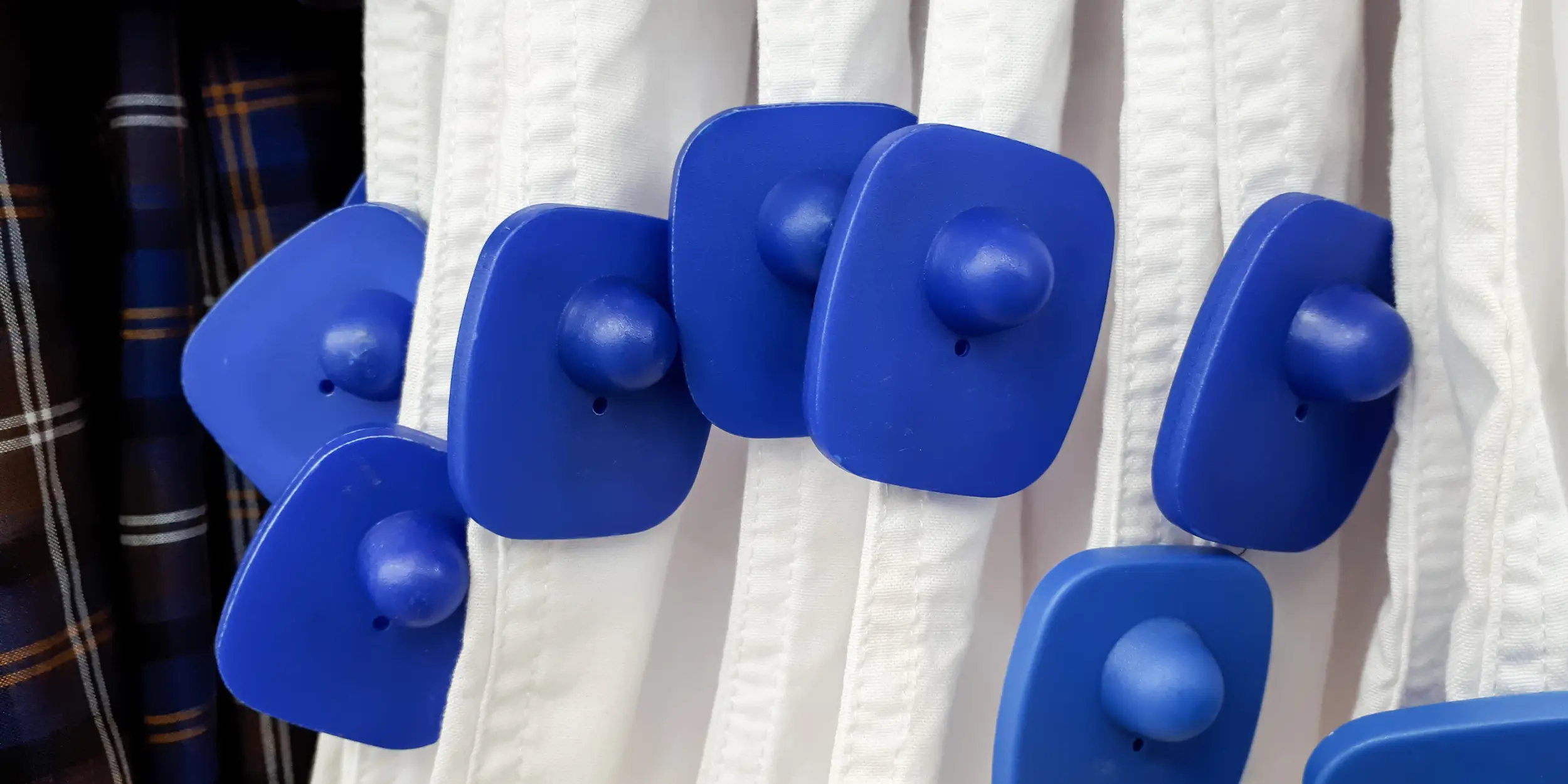

RFID helps reduce loss and fight counterfeiting in the textile industry

Each RFID tag is assigned a unique, non-duplicated ID code, so businesses can easily track the exact “journey” of a product from the place of production to the place of consumption. This helps to minimize counterfeit goods, fake goods and loss of goods during transportation, storage and retail.

On the other hand, with NFC technology, users can use their smartphones as RFID readers to scan and check the authenticity of products, optimize the experience, thereby strengthening trust in the brand. See details in the article: “RFID Anti-Counterfeiting – Advantages and Applications“.

Comply with sustainability standards

From 2026, the EU requires all garment products exported to the market to have a Digital Product Passport (DPP) – a digital product passport, clearly stating the ingredients, production process, information on responsibility, instructions for use, recycling information, etc. RFID is the ideal “tool” to record and transmit data throughout from factory to store in the most effective way.

Automate garment factory management and operation processes

With RFID technology, the operation and management processes of garment factories will be automated, significantly optimizing time. When importing or exporting goods, just put the pallet with RFID tag through the RFID reader, all data will be updated immediately.

In addition, RFID technology also brings many new applications such as automatically identifying new products brought in by customers, automatic payment counters, supporting product search in stores with handheld RFID readers, etc. For garment factories and businesses in Vietnam, investing in RFID is not only a solution to improve internal operational efficiency, but also a strategic step to integrate and compete with the global market.

RFID Applications in Apparel

Accordingly, RFID has been widely applied in the textile industry, in all stages, from production, warehouse management, logistics to retail,… Each link is optimized thanks to the ability to accurately track and transparently track data that RFID brings.

Textile RFID applications include:

- RFID applications in production, progress tracking and finished product management.

- Error tracking: If the product has technical errors, RFID allows tracing back to the batch of raw materials, production stages, workers, etc.

- Automate the import, storage and export processes.

- RFID applications in detailed management of raw materials such as fabric, buttons, threads, etc.

- RFID applications in logistics, acting as a “magic eye” to monitor goods in real time.

- In the retail channel, RFID helps create many new experiences for customers, typically including quick product search, smart fitting rooms, quick in-store counting, quick payment to reduce waiting time, etc.

Thus, RFID does not only stop at the role of warehouse management but also covers the entire value chain of the garment industry, from production, warehousing to retail. This is a technology that helps businesses optimize operating costs, while meeting global standards.

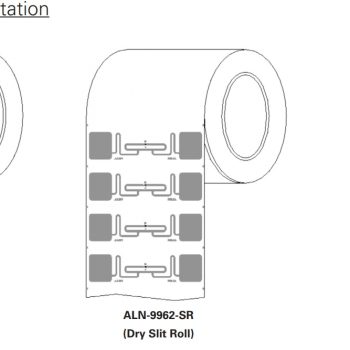

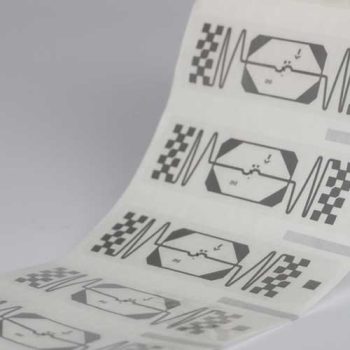

Types of RFID Labels in the Textile Industry

In the textile industry, choosing the right type of RFID label is a decisive factor in the effectiveness of the entire system implementation. Depending on the purpose of use, mounting location and operational requirements, businesses can consider choosing the appropriate type of RFID label.

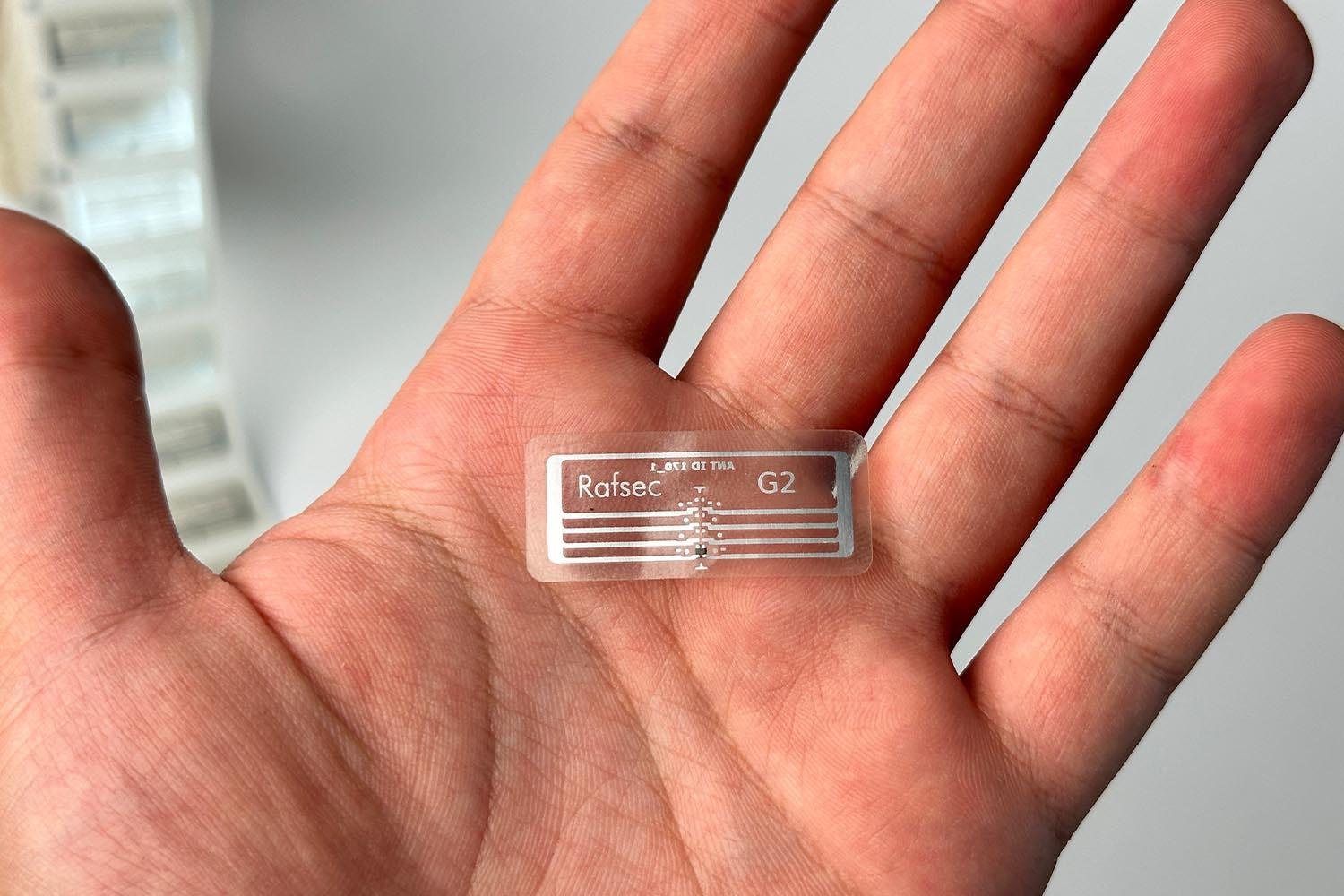

RFID hang tag

This is a type of RFID tag produced in the form of a paper label or a plastic RFID tag hanging outside the product. This RFID tag contains a UHF RFID chip with the ability to read far away, read many products at the same time, easy to remove when the product is sold, saving maximum costs. The RFID plastic tag in the form of a hang tag is suitable for most garments, clothes, accessories,…

RFID laundry label

This type of RFID tag is usually fixed to the laundry label inside the product, is heat resistant, and has a lifespan equivalent to the product’s life cycle. The advantage of this type of RFID tag is that it allows for traceability and effective warranty management.

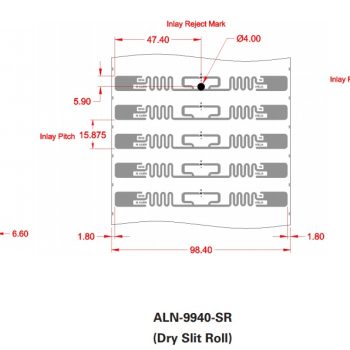

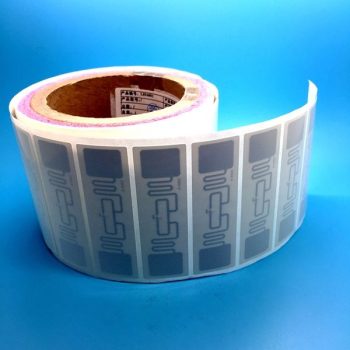

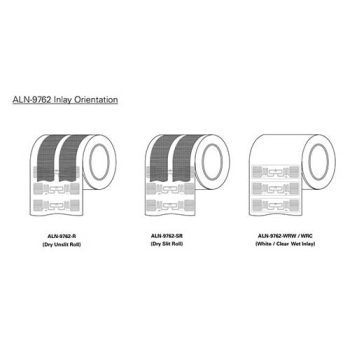

IT Nam Viet specializes in processing and distributing a variety of RFID tags and labels in garments according to customer requirements, high quality, superior durability and reasonable prices. Below are popular types of RFID textile tags and labels, customers can refer to more:

Textile RFID System Implementation Guide

Accordingly, to deploy a textile RFID system, you need to follow these steps:

- Step 1: Review the current business process; determine the purpose, set clear plans and goals.

- Step 2: Select RFID equipment including: RFID card reader, RFID card, antenna, software, determine tag location,…

- Step 3: Demo on a very small scale to see the performance and evaluate, analyze the effectiveness of the solution.

- Step 4: Deploy the entire system on a large scale, combine training of personnel to operate and manage the RFID system.

See details in the article: “Instructions for Newcomers to Use RFID Cards from IT Expert Nam Viet“.

FAQs – Frequently Asked Questions About Textile RFID Tags

Below are answers to frequently asked questions about RFID in the textile industry, readers can refer to more:

Can barcode technology be completely replaced by RFID in textiles?

NO. Ideally, these two technologies should be deployed in parallel, ensuring cost optimization and operational efficiency. Barcode technology can be used in small retail stores, simple applications. Meanwhile, businesses can apply RFID in bulk inventory operations, supply chain management,…

Is textile RFID implementation expensive?

YES. RFID costs depend on many factors: type of RFID device, RFID label, software, related service fees, etc. However, compared to traditional technologies, the cost of RFID implementation will be many times higher, in return, the management process will be more efficient with almost absolute accuracy.

Can RFID tags in the textile industry prevent counterfeiting?

YES. Each product is tagged with an RFID tag with a unique, non-duplicated identification code. Therefore, customers can use their smartphones to scan and authenticate the origin of the goods.

Are RFID tags laundry resistant?

YES. However, depending on the card type, the heat resistance level is not the same.

How long does it take to deploy an RFID system for textile and garment businesses?

RFID deployment time depends on many factors: business scale, investor requirements, usually, this time is about 10 – 20 days, divided into many stages, local testing and full deployment.

Does Nam Viet IT provide RFID solutions for the textile industry?

YES. IT Nam Viet is proud to be a prestigious unit in the field of RFID in Vietnam, specializing in providing multi-industry and multi-field RFID solutions, including: RFID textile, RFID in library management, RFID in healthcare, RFID in schools,… We provide genuine, quality RFID readers, RFID cards, management software, RFID printers,… with the best prices on the market.

Nam Viet IT owns a team of technicians with many years of experience in RFID implementation in various industries, committed to providing dedicated, thoughtful support and working with the highest sense of responsibility. We do not just stop at being a service provider, we also support strategic consulting, staff training and long-term companionship with the project.

RFID is no longer a “future technology”, RFID has become the “standard of the present” in the global textile industry. Therefore, finding and choosing a reputable RFID implementation unit will determine the success of the project. IT Nam Viet is a reputable RFID technology partner in Vietnam, please call us immediately via Hotline (+84) 962 888 179 when you have a need!

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt