The mining industry plays an important role in the economic development of many countries, of which Vietnam is no exception. Accordingly, some challenges that cannot be ignored when mentioning the mining industry are harsh working environment, large scale, many heavy equipment, many workers, and high risk of accidents, … Therefore, RFID in mining helps bring many significant benefits, improve safety and efficiency. The following article of IT Nam Viet will help you explore in detail the information related to the application of RFID technology in mining, follow and don’t miss it!

Why RFID Is A Good Solution In Mining?

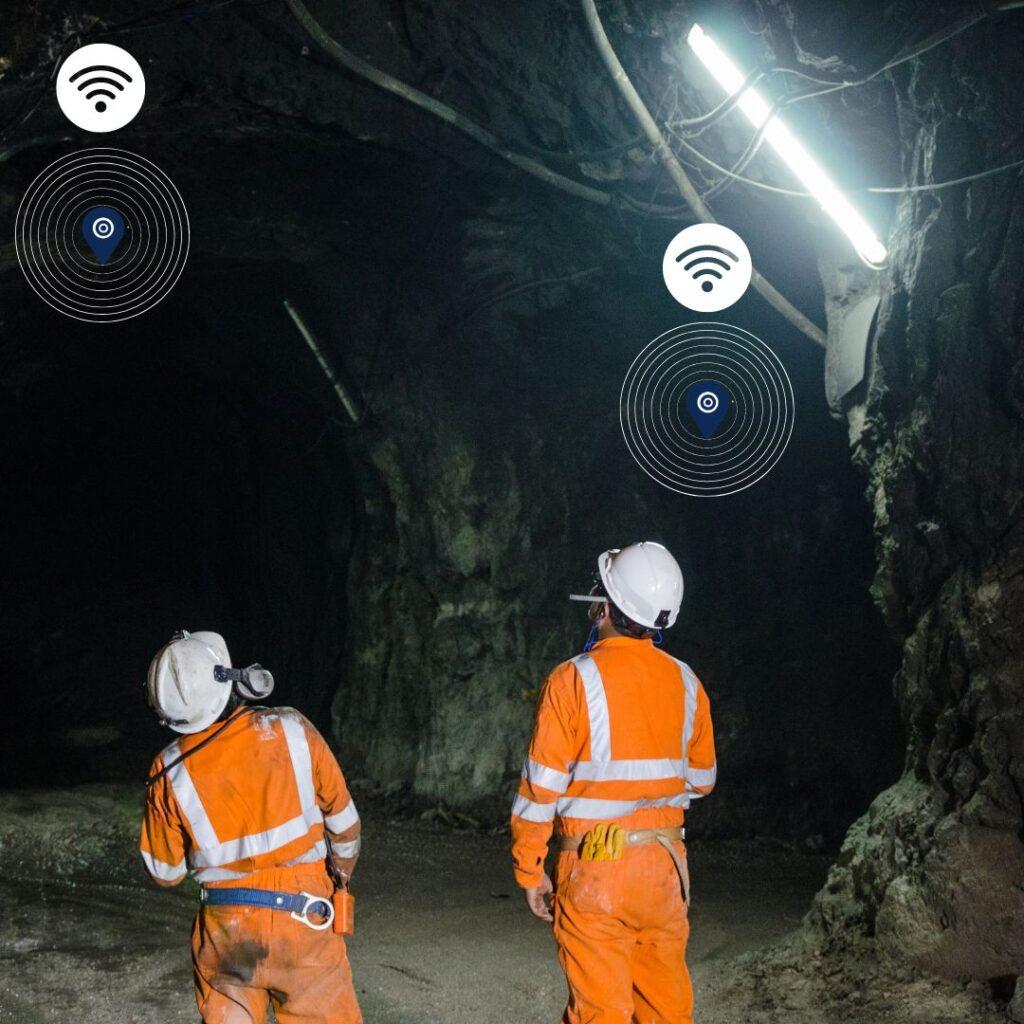

RFID is a technology for identifying and collecting data via radio waves, widely used in many different industries and fields, meeting the automation needs in the operation and management of enterprises in Vietnam. An RFID system in the mining industry includes the following basic components: RFID card, RFID reader, antenna, central software.

Accordingly, RFID tags and RFID labels will be attached to workers, trucks, excavators, drills, materials, etc. RFID Readers will be placed at mine gates, drilling areas, warehouses, etc. When the tag passes through the coverage area, the data will be updated and sent to the central management system in real time, so that the unit can monitor all mining activities transparently, quickly and with high accuracy.

Decoding the reasons for applying RFID technology in the mining industry today:

Firstly, RFID technology has the ability to track and monitor activities in the coverage area in real time. This means that businesses will monitor the location and operating status of each area immediately and accurately. The data collected quickly at high speed will help the management unit make quick decisions.

Second, RFID contributes to enhancing labor safety. When an incident occurs, the system will alert the location of each worker to deploy timely rescue. Of course, with the RFID solution, only those with a valid RFID card can enter the mining area, minimizing illegal intrusion and ensuring worker safety.

Third, RFID helps automate processes, thereby significantly reducing operating costs. Data is automatically updated instead of manual inventory, minimizing unnecessary errors.

Fourth, with RFID technology, the management and maintenance of equipment and machinery also becomes simpler and more accurate, minimizing unexpected incidents.

In addition, with the ability to combine with AI,… RFID opens up comprehensive management prospects for the mining industry in the future. This is a “revolutionary” technology in mining, helping businesses ensure both efficient production and human protection. Regarding this issue, we invite you to follow the details in the article: “RFID With Artificial Intelligence (AI) – A Breakthrough Combination in the Digital Age“.

Application of RFID Technology in Mining Today

Below are RFID technology applications in mining that your business can refer to:

Application of RFID technology in human resource management and labor safety in the mining industry

RFID is used in the mining industry to locate personnel. Accordingly, each worker will be given an RFID card with a unique identification code, then the RFID reader system will record the location of each person in real time, helping to accurately manage the number of personnel in the mine.

Safety is always the top priority in mining. In case of an incident, thanks to the ability to accurately locate the worker’s position, rescue and relief work will be carried out more effectively. The RFID system is immediately activated to alarm and quickly carry out rescue procedures, bringing workers to safety. In particular, RFID is used in access control for each area, only those with valid RFID cards are allowed to enter that area, ensuring compliance with safety regulations at the construction site.

RFID application in vehicle management at mines

By attaching RFID tags to equipment such as excavators, drills, etc., businesses can easily track machine status, operating hours, productivity, maintenance history, etc. Using RFID in vehicle management will bring many significant benefits, improve accuracy, and reduce labor costs. RFID can also help reduce losses due to theft or damage.

RFID applications in material and warehouse management

With RFID technology, all materials, explosives, ores,… are tagged with RFID from import to export, the system automatically controls, reducing theft or data errors. RFID data is synchronized with business management software, creating clear transparency.

RFID monitoring of mining environment at mine

RFID can be integrated with IoT sensors to monitor critical factors such as gas concentrations, dust, vibration, temperature, humidity, etc. This can help businesses minimize risks and comply with environmental safety regulations.

Challenges When Deploying RFID Systems in Mining

In fact, the challenge of deploying RFID systems in mining lies not only in the cost factor but also in the harsh environmental characteristics. Coal mines, ore mines,… are places with very high dust and humidity, many metal compounds,… all of which significantly affect the reading and writing ability of RFID card readers.

Besides, RFID costs are quite high, including RFID card costs, RFID readers, antennas, management software, etc. Moreover, RFID technology in mining is relatively unfamiliar to some businesses, so training personnel to operate the system is also a big challenge for the units.

Answering Frequently Asked Questions About RFID Mining

Below is information to answer some questions about RFID applications in mining, please read:

Is RFID technology capable of operating in harsh environmental conditions?

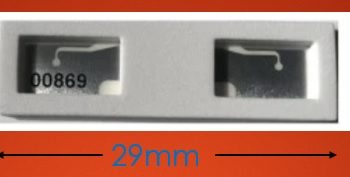

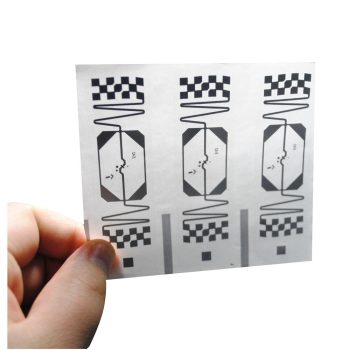

YES. Currently, RFID card manufacturers have produced water-resistant and metal-resistant RFID tags and labels that allow them to operate well in humid environments. You can refer to the types of RFID cards distributed by IT Nam Viet below:

Can RFID be replaced by barcodes in mining?

YES. However, compared to RFID technology, barcodes have more limitations, they can only read one tag at a time, and cannot read multiple tags at the same time. Of course, this greatly affects the performance of the construction site. Regarding this issue, we invite you to refer to the article: “Distinguishing Between Barcodes and RFID, Which Technology Should Be Used?“.

Nam Viet IT – Comprehensive RFID Solution Provider in Vietnam

IT Nam Viet is proud to be one of the pioneers in the field of providing and implementing RFID technology in Vietnam. We have more than 10 years of experience in the industry, have successfully implemented hundreds of projects of different sizes, committed to bringing customers comprehensive RFID solutions at the most competitive costs in the market.

Before consulting on solutions, the staff of IT Nam Viet conducts a field survey, grasps the characteristics and desires of the investor, and then considers and proposes the most effective solutions for the business. At IT Nam Viet, we are able to “tailor” solutions according to the actual needs of customers, optimize costs and increase operational efficiency for the unit.

IT Nam Viet is always ready to support customers 24/7, bringing absolute peace of mind to businesses throughout the system operation process. With a commitment to authenticity, prestige, and professionalism, IT Nam Viet increasingly affirms its position as the leading RFID supplier in Vietnam. If you need service consultation, please contact IT Nam Viet via Hotline (+84) 962 888 179 for support!

My name is Le Nam Viet, currently FOUNDER & CEO of Nam Viet IT Company, I graduated from Ho Chi Minh Polytechnic University. I have more than 3 years of experience providing RFID chip technology solutions, RFID scanners, barcode labels and barcode readers. It’s a pleasure to share my knowledge with readers.

Tiếng Việt

Tiếng Việt